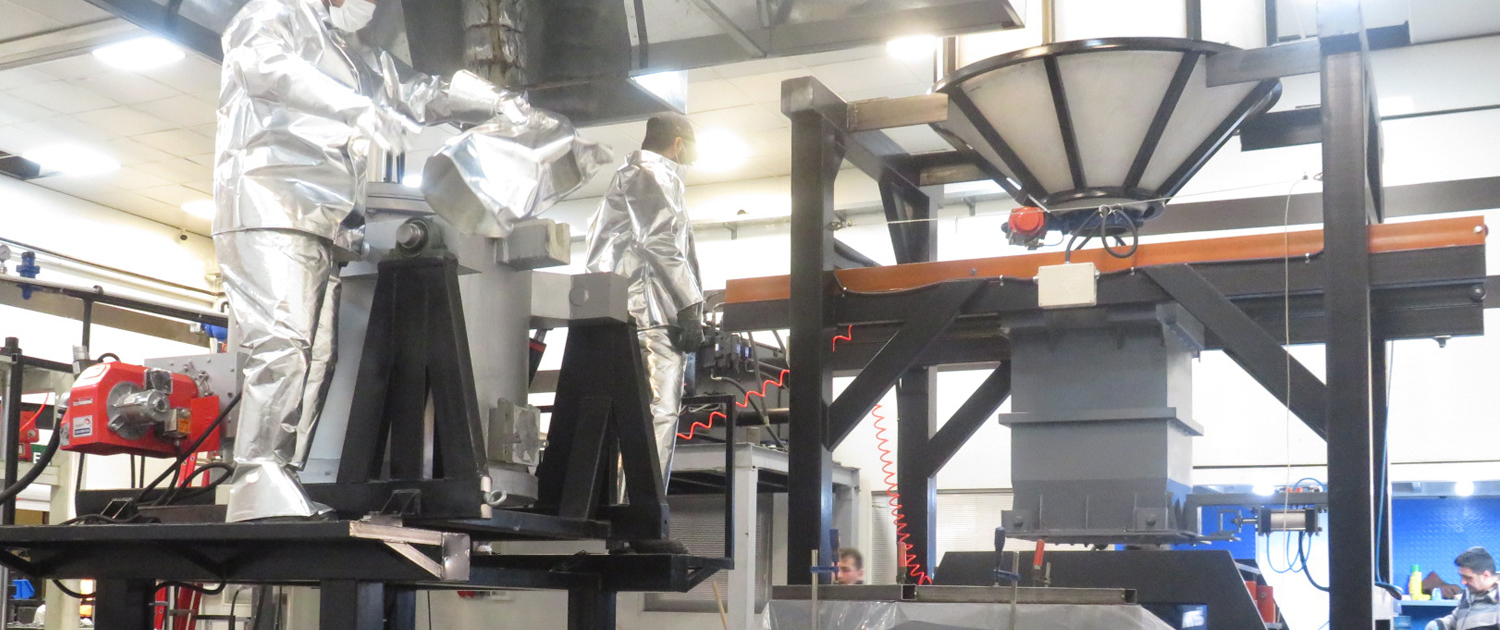

The Metallurgy Department at KATS L.T.D serves as the cornerstone of our commitment to excellence and innovation in materials science. Our dedicated team of metallurgists plays a pivotal role in ensuring the optimal performance and reliability of the metallic components used in our products. With a focus on material selection, quality assurance, and process optimization, the department is at the forefront of enhancing both product quality and production efficiency. We pride ourselves on staying at the cutting edge of metallurgical advancements through continuous research and development initiatives. As we strive for excellence, the Metallurgy Department also plays a crucial role in cost management, regulatory compliance, and fostering strong relationships with material suppliers. Our commitment to a culture of continuous improvement ensures that the metallurgy team remains agile and responsive to the evolving needs of our dynamic manufacturing environment. Through these efforts, the Metallurgy Department embodies our dedication to delivering products that not only meet but exceed the highest industry standards.

At KATS Ltd., our Metallurgy Department is not just a cornerstone but the driving force behind the exceptional quality and innovation in our products. Our mission extends into the following intricate details:

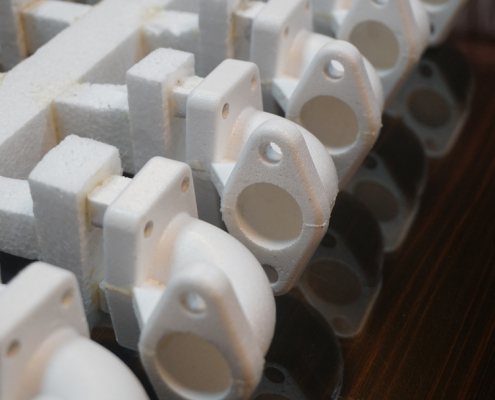

1. Precision in Material Selection and Testing:

– In-depth analysis of material characteristics, considering mechanical, thermal, and chemical properties alongside application-specific requirements.

– Employing advanced testing methodologies, including non-destructive testing, to ensure a meticulous assessment of material integrity.

2. Unwavering Quality Assurance:

– Integration of state-of-the-art quality control technologies and methodologies, such as computer-aided inspection systems, to guarantee the highest product standards.

– Continuous monitoring and real-time feedback loops to swiftly address any deviations and ensure a consistent level of excellence

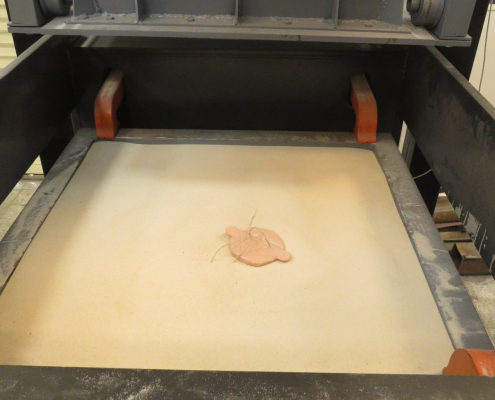

3. Innovative Process Optimization:

– Utilizing simulation tools to model and optimize manufacturing processes, minimizing waste, energy consumption, and cycle times.

– Spearheading cross-functional teams dedicated to research-driven process innovations that enhance both efficiency and environmental sustainability.

4. Strategic Research and Development:

– Maintaining a dedicated research wing within the Metallurgy Department focused on exploring emerging materials, alloys, and processes.

– Collaborating with external research institutions and industry experts to stay ahead of the curve in metallurgical advancements.

5. Thorough Failure Analysis:

– Implementing advanced techniques, such as root cause analysis and metallurgical microscopy, for comprehensive failure investigations.

– Utilizing predictive modeling to anticipate potential failure points and proactively implement preventive measures.

6. Cost-Effective Material Management:

– Leveraging advanced cost modeling tools to analyze the life cycle costs of materials and processes.

– Implementing lean manufacturing principles to optimize material usage and minimize environmental impact.

7. Regulatory Excellence:

– Maintaining a dedicated regulatory compliance team within the Metallurgy Department to ensure adherence to evolving industry standards and regulations.

– Proactively engaging with regulatory bodies to contribute to the development of ethical and sustainable metallurgical practices.

8. Culture of Continuous Improvement:

– Implementing employee-driven continuous improvement programs, encouraging innovative ideas and solutions from every member of the Metallurgy Department.

– Regularly conducting internal audits to identify areas for improvement and foster a culture of accountability and excellence.

9. Strategic Supplier Relationships:

– Establishing long-term partnerships with suppliers, working collaboratively on research initiatives, and engaging in joint efforts to enhance the quality and availability of materials.

– Implementing vendor certification programs to ensure our suppliers meet stringent quality and ethical standards.

10. Investment in Employee Development:

– Providing ongoing training opportunities for Metallurgy Department personnel, including workshops, certifications, and participation in industry conferences.

– Fostering a culture of knowledge-sharing and mentorship within the department to nurture the next generation of metallurgical leaders.

At KATS Ltd., our Metallurgy Department is dedicated to not only meeting but exceeding industry standards, continually pushing the boundaries of what is possible in materials science and manufacturing.