KATS Ltd. Turbochargers

Mastering the Turbocharger Craft from Concept to Drive

1. Designing the Powerhouse:

– Conceptualization Mastery: Our engineers collaborate to define turbocharger specifications, delving into horsepower goals,

boost requirements, and engine compatibility.

– Market-Driven Designs: Conducting in-depth market research to align our designs with evolving industry trends and customer needs.

– Feasibility Insights: Rigorous feasibility studies to evaluate proposed designs in terms of cost, materials, and manufacturing processes.

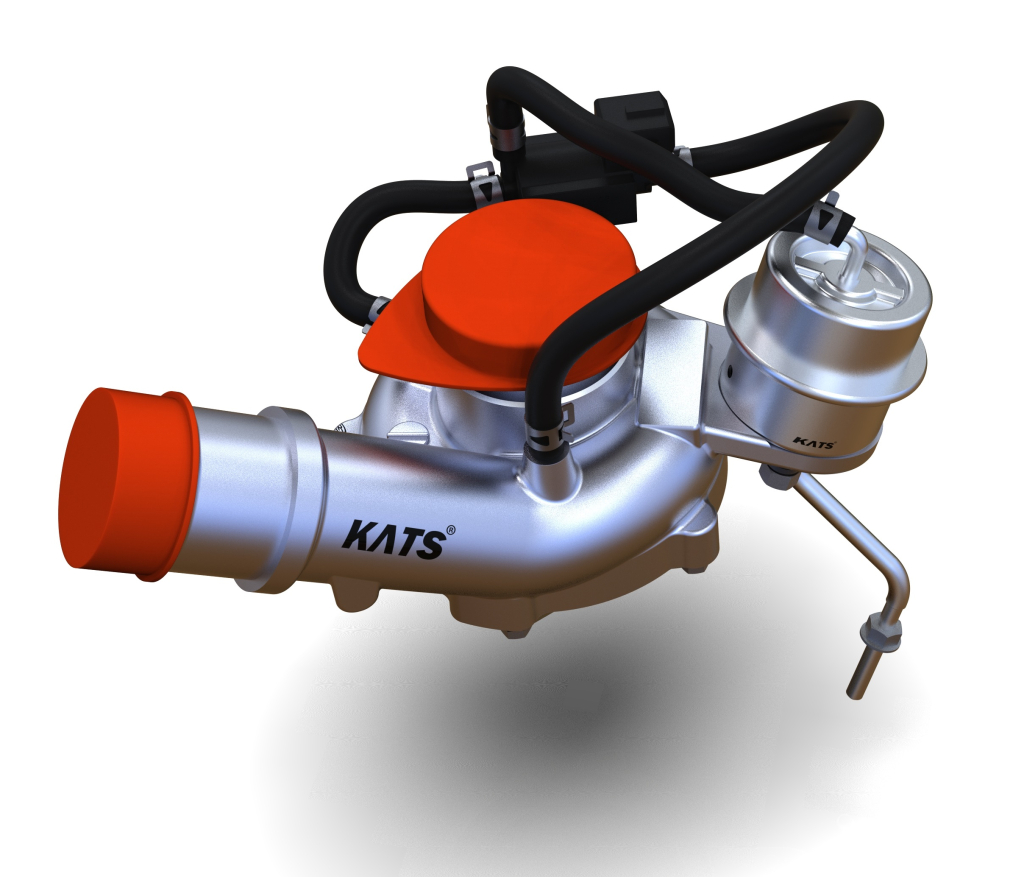

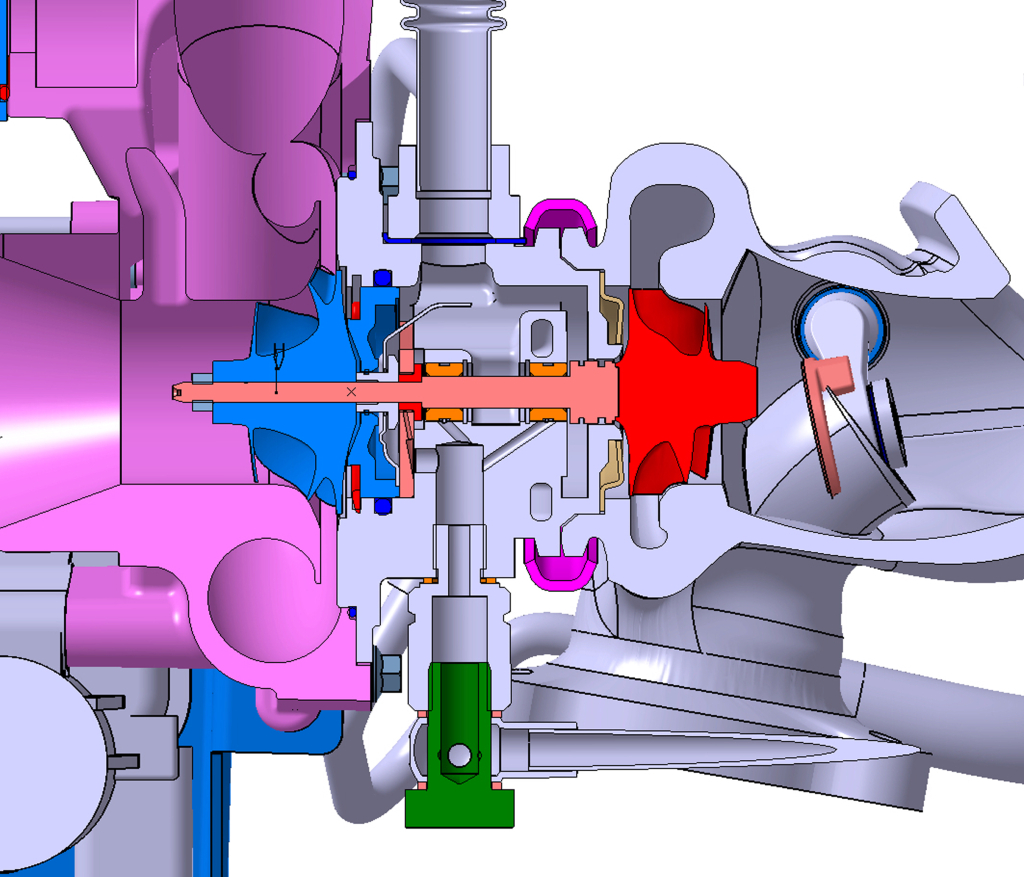

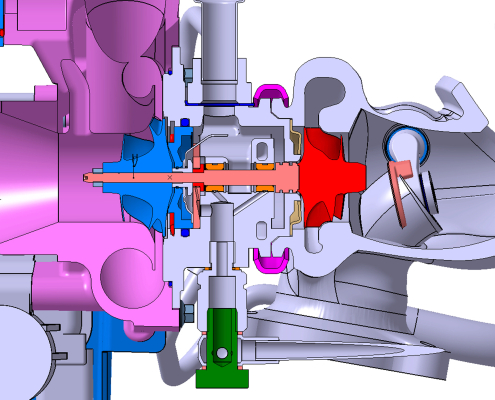

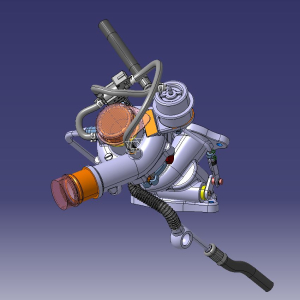

2. Digital Mastery with CAD:

– Engineering Artistry: Our design team employs cutting-edge CAD software to sculpt detailed 3D models for each turbocharger component.

– Iterative Brilliance: Iterative refinement based on simulations and analysis, ensuring optimal performance and manufacturability.

– Collaborative Excellence: Regular design reviews involving cross-functional teams, fostering collaborative creativity.

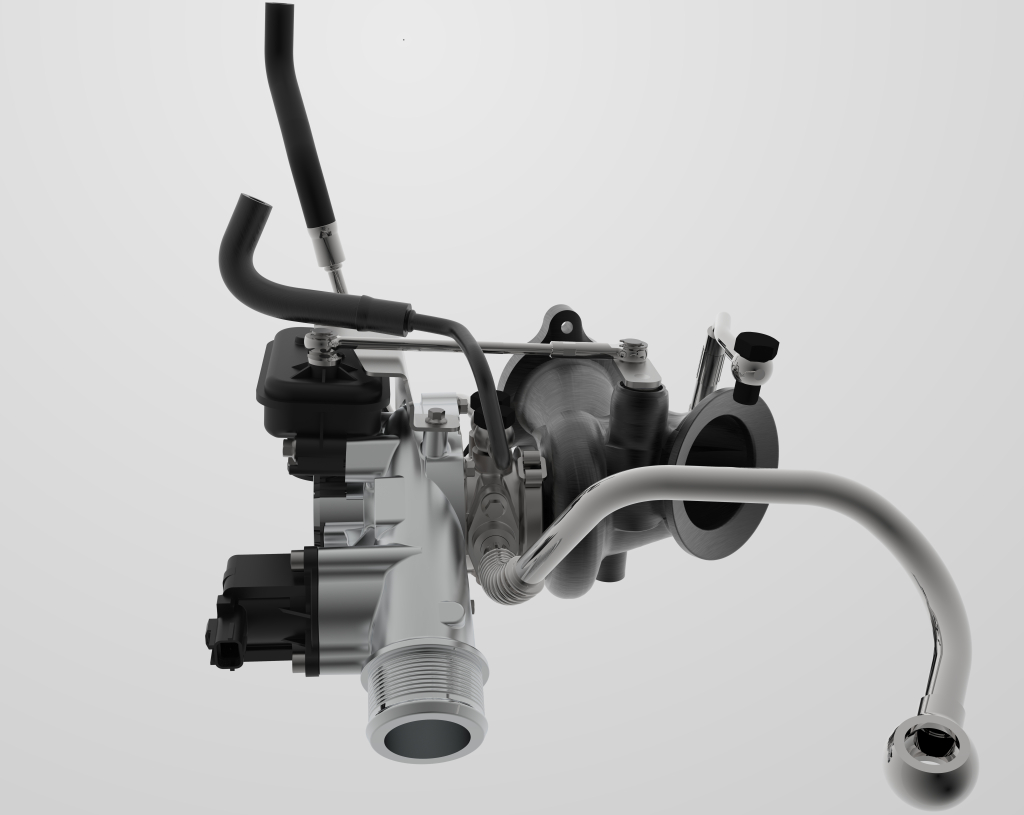

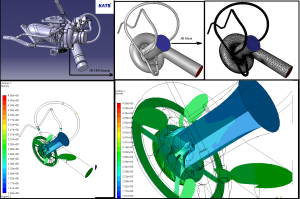

3. Simulating Triumph with CAE:

– Structural Fortitude: CAE tools simulate stresses and strains on components, fortifying structural integrity under varying loads.

– Thermal Dynamics Prowess: In-depth analysis of heat dissipation, thermal expansion, and stress under extreme temperature conditions.

– Fluid Dynamics Mastery: Simulating airflow dynamics to optimize pressure ratios and efficiency, a key parameter in our design philosophy.

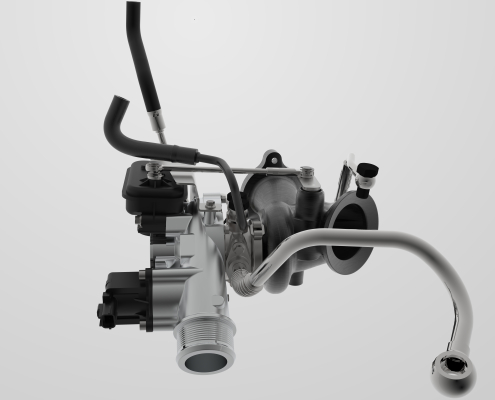

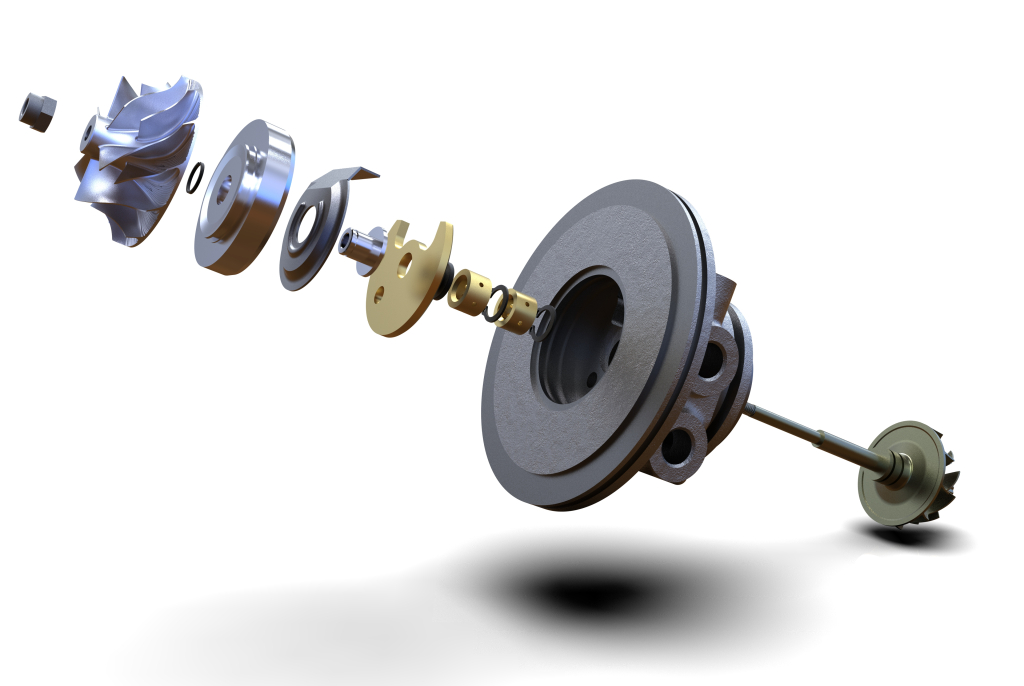

4. Prototyping and Sampling:

– Rapid Prototyping Excellence: Employing 3D printing to bring digital designs to life for initial testing and validation.

– Material Selection Artistry: Rigorous testing of materials to select the optimal combination for strength, heat resistance, and weight.

– Small-Scale Production Vision: Initiating limited production runs to refine manufacturing processes and gauge real-world performance.

5. Testing the Limits:

– Bench Testing Brilliance: Subjecting turbochargers to comprehensive bench testing to evaluate performance, efficiency, and response.

– Dynamic Balancing Precision: Utilizing high-precision equipment to achieve the perfect balance in rotating components.

– Heat Soak Mastery: Exposing turbochargers to extended high-temperature conditions to assess durability and heat management.

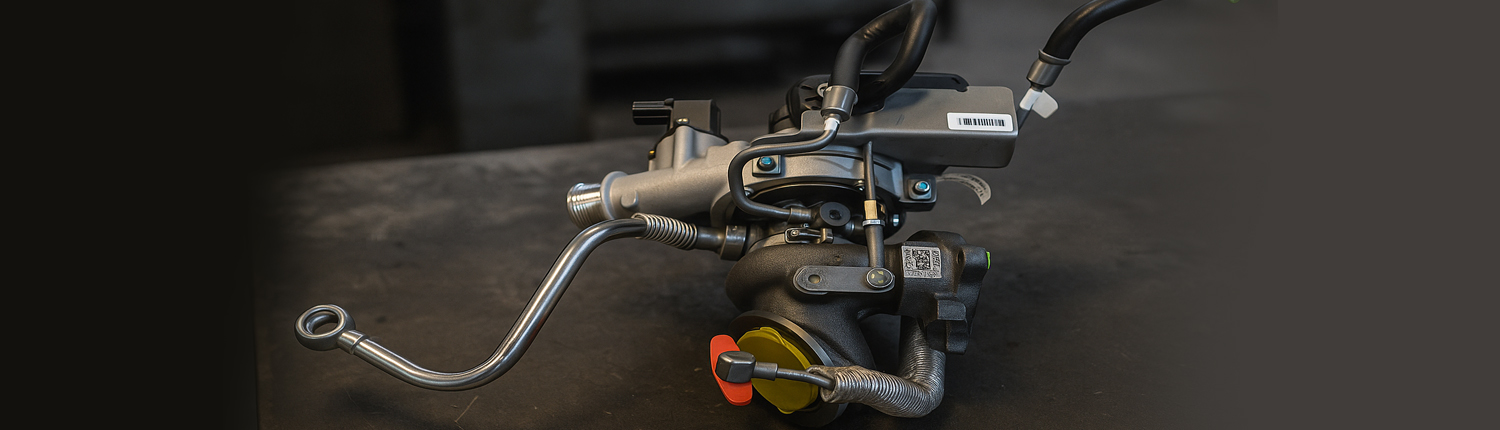

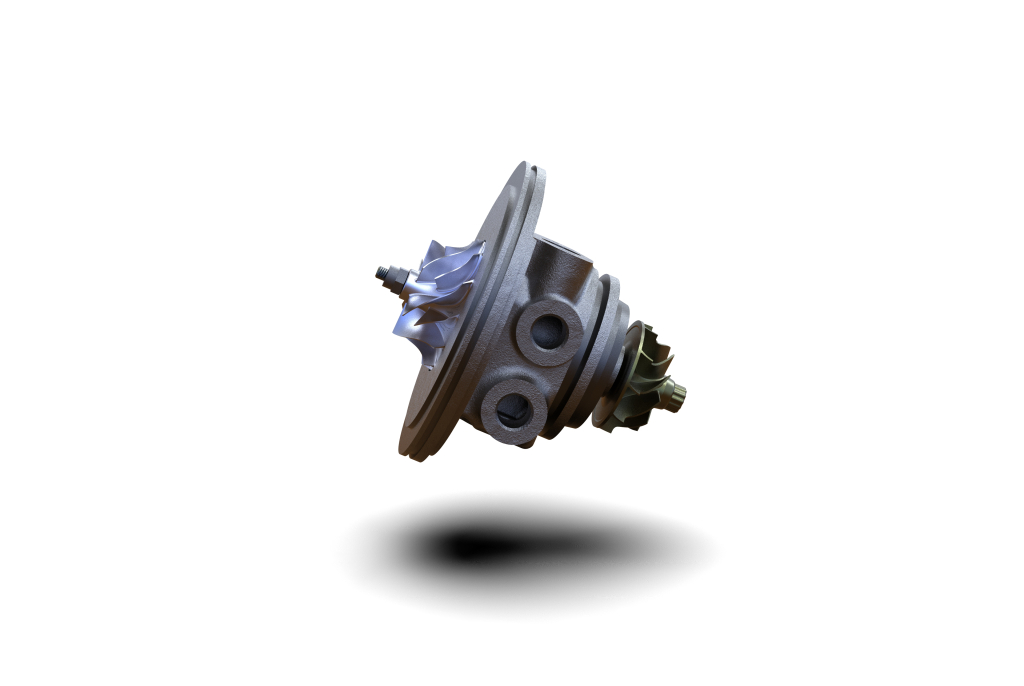

### 6. Precision in Manufacturing:

– Casting/Forging Expertise: Employing advanced casting and forging techniques for manufacturing critical components.

– Machining Precision: Ensuring exact specifications through precision machining for critical components.

– Craftsman Assembly: Our skilled technicians meticulously assemble turbochargers, adhering to detailed procedures and stringent quality checks.

– Dynamic Balancing at the Core: Balancing rotating assemblies during manufacturing to embed precision from the core.

### 7. Final Testing for Unrivaled Performance:

– Performance Testing Prowess: Rigorous final testing to validate that each turbocharger surpasses design specifications.

– Leak Testing Assurance: Ensuring airtight integrity in the fully assembled unit.

– Endurance Mastery: Subjecting turbochargers to prolonged operation to affirm long-term reliability.

### 8. Global Excellence in Packaging and Distribution:

– Secure Packaging Mastery: Impeccable packaging to safeguard turbochargers during transportation.

– Efficient Global Distribution: Employing strategic distribution networks for swift and efficient global delivery.

### 9. Customer-Centric Support:

– Technical Excellence: Offering continuous technical support, comprehensive documentation, and direct assistance for our valued customers.

– Feedback Elevation: Actively seeking customer feedback through multiple channels to continually elevate our designs and processes.

At KATS Ltd., every stage of our turbocharger manufacturing process is a testament to precision, innovation, and a relentless pursuit of excellence. Welcome to a realm

where each turbocharger is more than an engine component; it’s a masterpiece engineered for unparalleled power and performance.